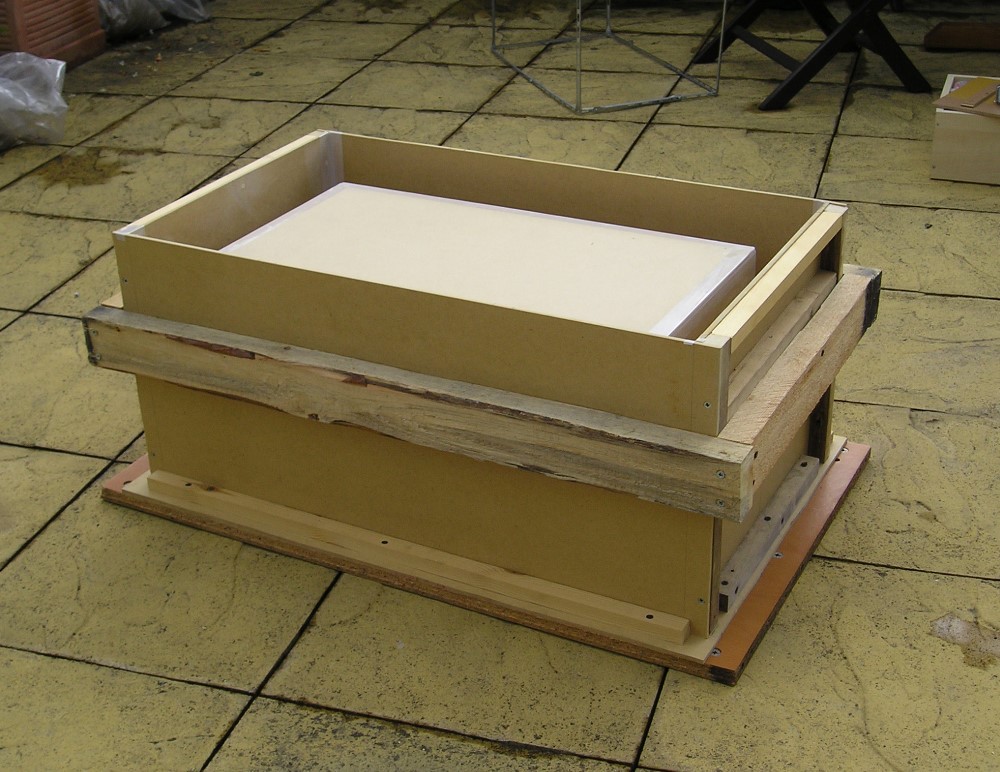

The idea was to build a fountain in three elements: a rectangular basin, a vertical stele and, on top, a triangular pediment. We wanted the water feature to be aesthetically pleasing and we added some authenticity by inserting a couple of bucket-rest bars into the basin. The moulds were made from sheets of medium-density fibreboard (MDF) and plywood from an old wardrobe.

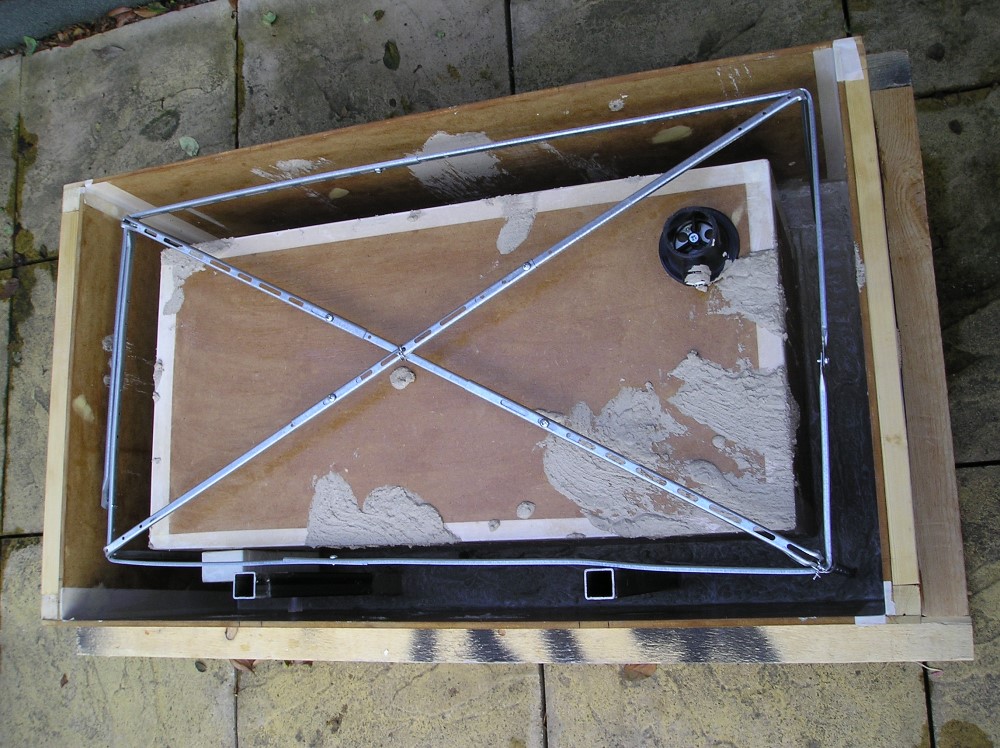

This is the mould for the basin: basically a box set in the middle of a larger box. The basin was cast upside down by filling the space between the two boxes as well as the rest of the larger box to the brim with concrete. The belt around the mould prevented the concrete from pushing the MDF walls to the outside.

A block of polystyrene was used to reserve the space for a recess inside the back wall of the basin to host the pump. The small horizontal plastic tube created a small tunnel through the wall for the pump’s electric cable and for the plastic tube that will run behind the stele to bring water to the spout.

We painted the inside of the mould with oil to, later, facilitate demoulding, put a metal cage inside the mould to re-enforce the basin’s walls, put the drainage outlet in place then we started filling with concrete. The two vertical hollow steel square bars (bottom of the picture) are set inside the back wall of the basin. Smaller rods fixed to the stele will later slide inside those bars.

The basin out of its mould and turned to its correct position. The bucket-rest bars were placed inside the mould before the concrete was poured.

The mouldings at the top of the basin came out quite neat.

The basin in its final place.

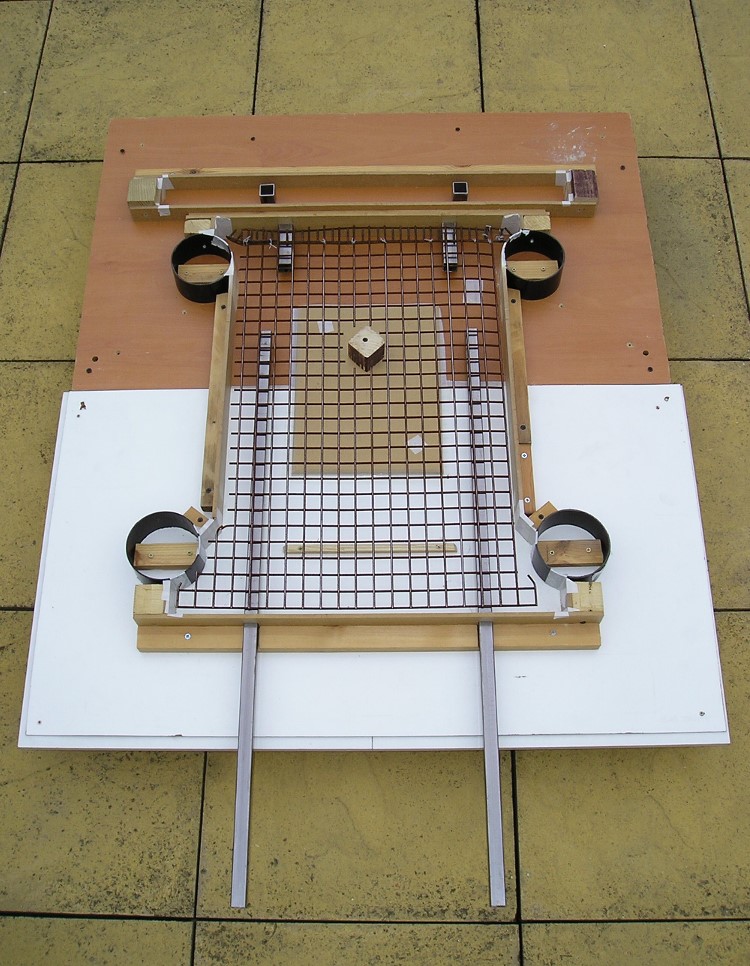

The mould for the stele. We used sections of PVC pipes to obtain curves. The long steel rods that protrude at the bottom will slide inside the hollow bars at the back of the basin. In the same way, the small sections of hollow bars, at the top of the stele, will receive the rods coming out of the pediment. The metal grid is for re-enforcement. The rectangular piece of MDF in the middle will create a decorative recess at the front of the stele around the water spout. The small cube of wood in the middle reserves a space for the water spout. It will be removed after demoulding.

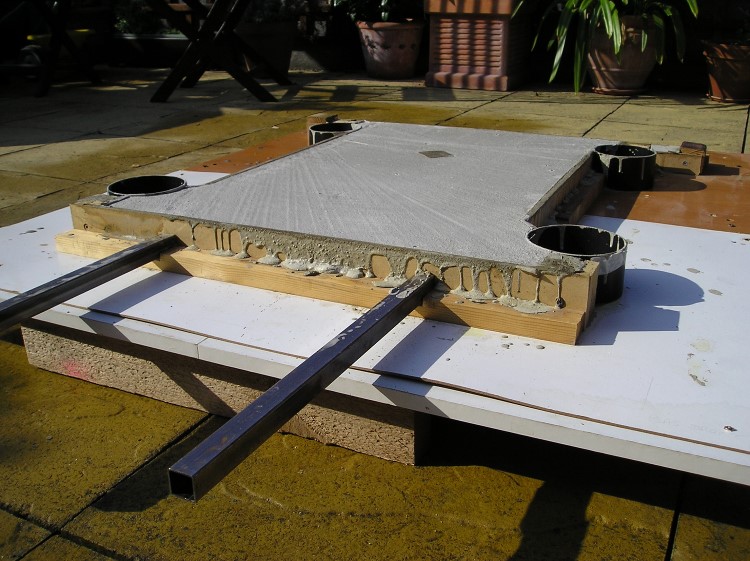

The mould for the stele was then filled with concrete. The top surface will be at the back of the stele. The bottom surface (the front of the stele) will be neater because there the concrete presses against the smooth surface of the mould.

The stele placed on top of the basin. The horizontal groove near the bottom was obtained by sticking a wooden rod at the bottom of the mould. It constitutes a key for a small ledge that we will add later.

This is the mould for the pediment. The round piece of MDF will create a decorative circular recess in the middle of the tympanum.

As for the stele, the top surface of the concrete will be at the back of the pediment.

The pediment, freshly out of its mould.

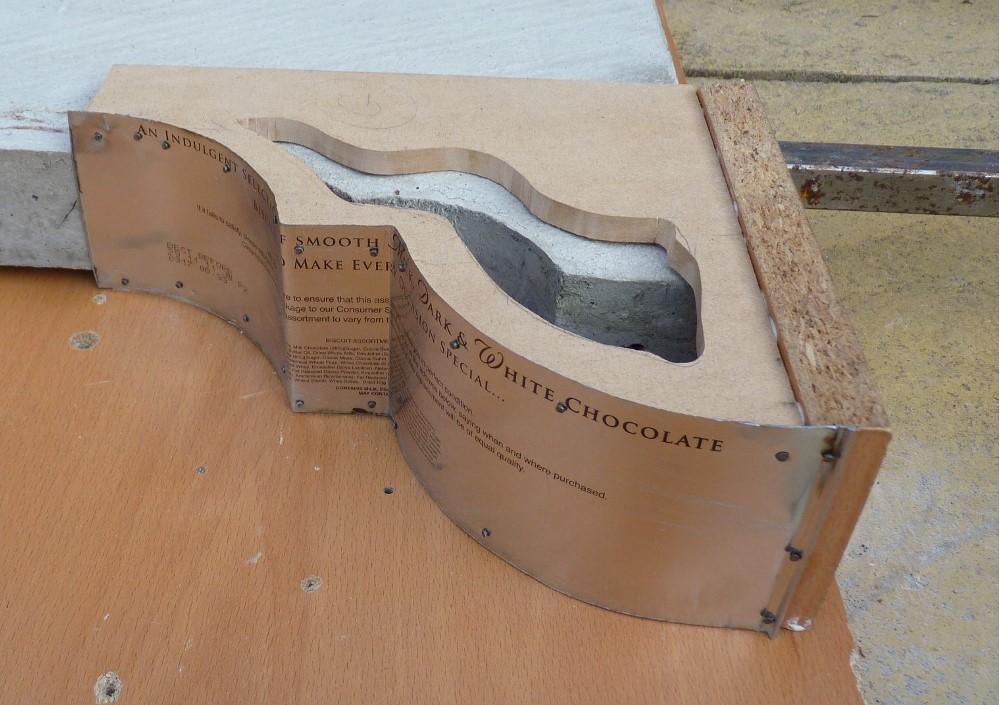

We were not happy with the original shape of the stele and decided to make its base wider. We cut the shape we wanted in a sheet of MDF.

We cut strips of tin out of a chocolate box and nailed them on the MDF, then poured the concrete through the holes at the top.

This time, we were happy with the general shape of the fountain. We then added an arch above the spout (half the depth of the original recess). Finally we added the ledge.

We shaped and placed the spout, coated the inside of the basin with waterproofing epoxy and painted the fountain.